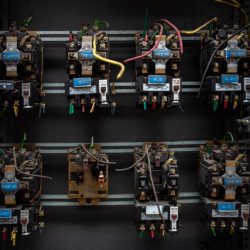

A Diesel Particulate Filter (DPF) is an essential component in modern diesel engines such as truck trailers, excavators, 4×4 trucks, etc., designed to reduce harmful emissions and ensure compliance with environmental regulations. Specifically, DPFs capture and store particulate matter (PM)—commonly referred to as soot—produced during the combustion process.

DPFs are typically installed in the exhaust system of diesel vehicles and work by using a network of fine ceramic channels or honeycomb-like structures. These channels are porous, allowing exhaust gases to pass through while trapping particulate matter.

Over time, the soot accumulated in the DPF is burned off during a process called regeneration, which prevents clogging and ensures the filter remains effective.

Modern innovations in DPF technology, such as Mammoth Equipment’s Diesel Particulate Filters, are purpose-built for specific applications, engine types, and back pressure specifications. These filters deliver consistent performance, achieving over 98% reductions in Diesel Particulate Matter, making them a reliable choice for ensuring compliance with emission standards.

Why Are DPFs Important?

The introduction of DPFs became necessary as global concerns over air quality grew. Diesel engines are known for emitting higher levels of particulate matter and nitrogen oxides (NOx) compared to petrol engines. These pollutants contribute to serious health issues, such as respiratory problems, and environmental concerns like smog and acid rain.

Regulatory bodies, such as the European Union with its Euro emissions standards and similar initiatives in the United States and Australia, mandate the use of DPFs in diesel vehicles to meet stringent emission targets. Without a DPF, a diesel vehicle cannot legally operate in many regions.

How Does a DPF Work?

DPFs operate through the following key processes:

- Filtration of Soot Particles

As exhaust gases pass through the filter, particulate matter is trapped in the honeycomb-like channels. These particles accumulate over time and require periodic removal. - Regeneration Process

Regeneration is the mechanism by which the accumulated soot is burned off to prevent blockages. It can occur in two main ways:- Passive Regeneration: Occurs automatically during normal vehicle operation when the exhaust temperature is high enough (e.g., highway driving) to burn off soot.

- Active Regeneration: Triggered by the vehicle’s engine control unit (ECU) when passive regeneration is insufficient. This process raises the exhaust temperature, often by injecting additional fuel, to burn off the soot.

- Ash Accumulation

While regeneration removes soot, it doesn’t eliminate all residues. Over time, non-combustible materials like ash from oil additives can accumulate, requiring manual cleaning or replacement of the DPF.

How Often Does a Diesel Particulate Filter Need Changing?

The lifespan of a DPF can vary widely based on several factors, including the vehicle’s make and model, driving habits, and maintenance practices. On average, a DPF is designed to last between 160,000 and 240,000 kilometres. However, there are instances where a DPF may require attention sooner.

Factors Influencing DPF Longevity

- Driving Habits

- Frequent short trips or stop-and-go traffic do not allow the exhaust system to reach the high temperatures necessary for passive regeneration, leading to faster soot buildup.

- Long-distance highway driving is ideal for maintaining a healthy DPF as it promotes passive regeneration.

- Fuel Quality

- Low-quality diesel with high sulfur content can lead to excessive soot production, clogging the filter more quickly.

- Premium diesel fuels with cleaning additives can help prolong DPF life.

- Engine Maintenance

- Regular oil changes using low-ash engine oils are crucial to prevent premature ash buildup in the DPF.

- Faulty components like injectors or turbochargers can increase soot production, causing the DPF to fail earlier.

- Regeneration Frequency

- A properly functioning regeneration system is essential for maintaining the DPF. Frequent interruptions to the regeneration process can result in clogging and potential damage.

Signs That Your DPF Needs Attention

It’s essential to recognize the warning signs of a failing or clogged DPF to prevent costly repairs. Common indicators include:

- Dashboard Warning Light

Most diesel vehicles are equipped with a DPF warning light that illuminates when the filter becomes clogged. - Loss of Engine Power

A clogged DPF restricts exhaust flow, leading to reduced engine performance and sluggish acceleration. - Increased Fuel Consumption

When the DPF is blocked, the engine works harder, consuming more fuel. - Excessive Smoke

Visible black smoke from the exhaust may indicate that the DPF is not functioning properly. - Frequent Regeneration Failures

If regeneration is unable to clear the soot buildup, professional intervention is required.

Maintenance and Replacement Costs

Cleaning vs. Replacement

- Cleaning: In many cases, a clogged DPF can be restored through professional cleaning, which removes soot and ash buildup. This process is significantly cheaper than replacement, costing between $300 and $700 AUD in Australia.

- Replacement: If the DPF is severely damaged or worn out, replacement may be the only option. The cost of a new DPF can range from $2,000 to $5,000 AUD depending on the vehicle and filter type.

Preventative Measures

- Drive Regularly at Highway Speeds: Allowing the exhaust to reach high temperatures aids in passive regeneration.

- Use Low-Ash Oils: These oils reduce ash buildup in the DPF.

- Fill Up with Quality Diesel: Premium fuels help reduce soot formation.

- Monitor Regeneration Cycles: Avoid interrupting the process to prevent soot buildup.

Frequently Asked Questions

Can I Remove the DPF from My Diesel Vehicle?

In many countries, including Australia, removing or bypassing the DPF is illegal and can result in heavy fines. Additionally, a vehicle without a functioning DPF will fail emission tests and cannot be registered.

What Happens If I Ignore a Clogged DPF?

Driving with a blocked DPF can cause severe engine damage, leading to costly repairs. Additionally, ignoring DPF issues can result in increased emissions, and violating environmental laws.

Does Every Diesel Vehicle Have a DPF?

Most modern diesel vehicles manufactured after 2009 are equipped with a DPF to comply with emissions standards. However, older models may not have this feature.

Conclusion

Diesel Particulate Filters play a critical role in reducing the environmental impact of diesel engines by capturing harmful soot particles. Proper maintenance, including regular cleaning and adherence to regeneration cycles, can ensure the longevity of a DPF, saving you from costly replacements.

Innovative solutions like Mammoth Equipment’s Diesel Particulate Filters offer tailored designs for specific applications, engine types, and back pressure specifications, ensuring reliable performance with over 98% reductions in Diesel Particulate Matter. By adopting good driving practices and using quality fuel, you can extend the life of your DPF and contribute to a cleaner environment.